WHO WE ARE

WHO WE ARE

As a comprehensive enterprise that has been established for more than 40 years, Tianjin Xinyue Steel Group dedicated to providing one-stop services for global steel projects. As a leading steel manufacturer in the industry , the group's business covers multiple production sectors: including the production and inventory of steel pipes and accessories, customized production of steel structure, and construction of piling projects, etc.Additionally to covering processing sectors that range from customized size, anti-corrosion processing to galvanizing processing, etc.

PRODUCTS

PRODUCTS

- ERW Steel Pipe

- SSAW Steel Pipe

- LSAW Steel Pipe

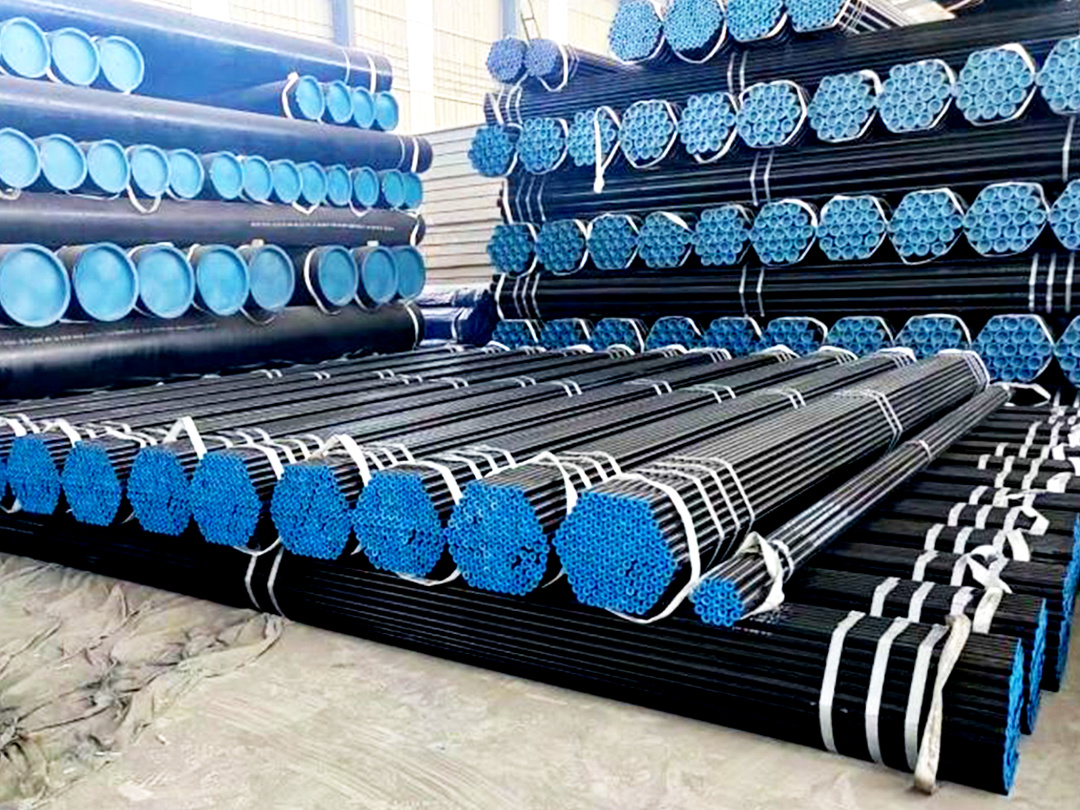

- Seamless Steel Pipe

- Hollow Section

- Scaffolding

- Sheet Pile

- Steel Structure

Casing Pipe

ERW is Electric Resistance Welded steel, refers to the manufacturing method whereby Round E.R.W Steel Tube, or Electric Resistance Welded Steel Pipe has its steel edges melted and welded to form a consistent cylindrical shape. Heat and pressure are combined to join the steel sheet to give you a very lightweight and easy to work with tubing for an array of engineering and construction requirements. It widely used in commercial settings for a vast array of possibilities include:

Bearing Piles,Driven Piles,Driven Piles,Combination Walls,Structural Sections,Threaded Micropile Casing,Sign Poles, Towers & Transmission Lines,Mining,Underground Garages, Bridge Abutments Levees, Storm Protection, Horizontal pipe, Geostructural Solutions, Solar Solutions.

Structure Pipe

ERW is Electric Resistance Welded steel, refers to the manufacturing method whereby Round E.R.W Steel Tube, or Electric Resistance Welded Steel Pipe has its steel edges melted and welded to form a consistent cylindrical shape. Heat and pressure are combined to join the steel sheet to give you a very lightweight and easy to work with tubing for an array of engineering and construction requirements. It widely used in commercial settings for a vast array of possibilities include:

Bearing Piles,Driven Piles,Driven Piles,Combination Walls,Structural Sections,Threaded Micropile Casing,Sign Poles, Towers & Transmission Lines,Mining,Underground Garages, Bridge Abutments Levees, Storm Protection, Horizontal pipe, Geostructural Solutions, Solar Solutions.

Low Pressure Pipe

ERW is Electric Resistance Welded steel, refers to the manufacturing method whereby Round E.R.W Steel Tube, or Electric Resistance Welded Steel Pipe has its steel edges melted and welded to form a consistent cylindrical shape. Heat and pressure are combined to join the steel sheet to give you a very lightweight and easy to work with tubing for an array of engineering and construction requirements. It widely used in commercial settings for a vast array of possibilities include:

Bearing Piles,Driven Piles,Driven Piles,Combination Walls,Structural Sections,Threaded Micropile Casing,Sign Poles, Towers & Transmission Lines,Mining,Underground Garages, Bridge Abutments Levees, Storm Protection, Horizontal pipe, Geostructural Solutions, Solar Solutions.

Petroleum Line Pipe,ERW Petroleum Line Pipe for Oil Transport

ERW is Electric Resistance Welded steel, refers to the manufacturing method whereby Round E.R.W Steel Tube, or Electric Resistance Welded Steel Pipe has its steel edges melted and welded to form a consistent cylindrical shape. Heat and pressure are combined to join the steel sheet to give you a very lightweight and easy to work with tubing for an array of engineering and construction requirements. It widely used in commercial settings for a vast array of possibilities include:

Bearing Piles,Driven Piles,Driven Piles,Combination Walls,Structural Sections,Threaded Micropile Casing,Sign Poles, Towers & Transmission Lines,Mining,Underground Garages, Bridge Abutments Levees, Storm Protection, Horizontal pipe, Geostructural Solutions, Solar Solutions.

Petroleum Line Pipe

SMLS pipe refers to seamless steel pipe, which is made of a whole piece of metal and has no joints on the surface. According to the production method, seamless pipe is divided into hot rolled pipe, cold rolled pipe, cold drawn pipe, extrusion pipe, pipe jacking and so on.

According to different uses, there are thick wall seamless steel pipes and thin wall seamless steel pipes.

Seamless steel pipe is mainly used for petroleum geological drilling pipe, petrochemical cracking pipe, boiler furnace pipe, bearing pipe and high-precision structural steel pipe for automobiles, tractors and aviation.

It is divided into two categories: general purpose (for water and gas pipelines and structural parts, mechanical parts) and special purpose (for boilers, geological exploration, bearings, acid resistance, etc.)

Low Pressure Pipe

SMLS pipe refers to seamless steel pipe, which is made of a whole piece of metal and has no joints on the surface. According to the production method, seamless pipe is divided into hot rolled pipe, cold rolled pipe, cold drawn pipe, extrusion pipe, pipe jacking and so on.

According to different uses, there are thick wall seamless steel pipes and thin wall seamless steel pipes.

Seamless steel pipe is mainly used for petroleum geological drilling pipe, petrochemical cracking pipe, boiler furnace pipe, bearing pipe and high-precision structural steel pipe for automobiles, tractors and aviation.

It is divided into two categories: general purpose (for water and gas pipelines and structural parts, mechanical parts) and special purpose (for boilers, geological exploration, bearings, acid resistance, etc.)

Structure Pipe

SMLS pipe refers to seamless steel pipe, which is made of a whole piece of metal and has no joints on the surface. According to the production method, seamless pipe is divided into hot rolled pipe, cold rolled pipe, cold drawn pipe, extrusion pipe, pipe jacking and so on.

According to different uses, there are thick wall seamless steel pipes and thin wall seamless steel pipes.

Seamless steel pipe is mainly used for petroleum geological drilling pipe, petrochemical cracking pipe, boiler furnace pipe, bearing pipe and high-precision structural steel pipe for automobiles, tractors and aviation.

It is divided into two categories: general purpose (for water and gas pipelines and structural parts, mechanical parts) and special purpose (for boilers, geological exploration, bearings, acid resistance, etc.)

Petroleum Line Pipe

LSAW steel pipe (Longitudinally Submerged Arc Welding abbreviated LSAW) is a professional expression term for longitudinally submerged arc welding, which is made of a single medium and thick plate as raw material, the steel plate is pressed (rolled) into a tube billet ina mold or forming machine, and is produced by double-sided submerged arc welding and expanded diameter.

The finished LSAW steel pipe has a wide range of specifications, good toughness, plasticity, uniformity and density of the weld, and has the advantages of large pipe diameter, pipe wall thickness, high pressure resistance, low temperature resistance and corrosion resistance.

In the construction of high strength and high quality long distance oil and gas pipelines, most of the steel pipes needed are large diameter thick wall straight seam submerged arc welded pipes.

Low Pressure Pipe

LSAW steel pipe (Longitudinally Submerged Arc Welding abbreviated LSAW) is a professional expression term for longitudinally submerged arc welding, which is made of a single medium and thick plate as raw material, the steel plate is pressed (rolled) into a tube billet ina mold or forming machine, and is produced by double-sided submerged arc welding and expanded diameter.

The finished LSAW steel pipe has a wide range of specifications, good toughness, plasticity, uniformity and density of the weld, and has the advantages of large pipe diameter, pipe wall thickness, high pressure resistance, low temperature resistance and corrosion resistance.

In the construction of high strength and high quality long distance oil and gas pipelines, most of the steel pipes needed are large diameter thick wall straight seam submerged arc welded pipes.

Structure Pipe

LSAW steel pipe (Longitudinally Submerged Arc Welding abbreviated LSAW) is a professional expression term for longitudinally submerged arc welding, which is made of a single medium and thick plate as raw material, the steel plate is pressed (rolled) into a tube billet in a mold or forming machine, and is produced by double-sided submerged arc welding and expanded diameter.

The finished LSAW steel pipe has a wide range of specifications, good toughness, plasticity, uniformity and density of the weld, and has the advantages of large pipe diameter, pipe wall thickness, high pressure resistance, low temperature resistance and corrosion resistance.

In the construction of high strength and high quality long distance oil and gas pipelines, most of the steel pipes needed are large diameter thick wall straight seam submerged arc welded pipes.

Category:

LSAW Steel Pipe

Structure Pipe

Keywords:

Structure Pipe

Casing Pipe

SMLS pipe refers to seamless steel pipe, which is made of a whole piece of metal and has no joints on the surface. According to the production method, seamless pipe is divided into hot rolled pipe, cold rolled pipe, cold drawn pipe, extrusion pipe, pipe jacking and so on.

According to different uses, there are thick wall seamless steel pipes and thin wall seamless steel pipes.

Seamless steel pipe is mainly used for petroleum geological drilling pipe, petrochemical cracking pipe, boiler furnace pipe, bearing pipe and high-precision structural steel pipe for automobiles, tractors and aviation.

It is divided into two categories: general purpose (for water and gas pipelines and structural parts, mechanical parts) and special purpose (for boilers, geological exploration, bearings, acid resistance, etc.)

Structure Pipe

SMLS pipe refers to seamless steel pipe, which is made of a whole piece of metal and has no joints on the surface. According to the production method, seamless pipe is divided into hot rolled pipe, cold rolled pipe, cold drawn pipe, extrusion pipe, pipe jacking and so on.

According to different uses, there are thick wall seamless steel pipes and thin wall seamless steel pipes.

Seamless steel pipe is mainly used for petroleum geological drilling pipe, petrochemical cracking pipe, boiler furnace pipe, bearing pipe and high-precision structural steel pipe for automobiles, tractors and aviation.

It is divided into two categories: general purpose (for water and gas pipelines and structural parts, mechanical parts) and special purpose (for boilers, geological exploration, bearings, acid resistance, etc.)

Low Pressure Pipe

SMLS pipe refers to seamless steel pipe, which is made of a whole piece of metal and has no joints on the surface. According to the production method, seamless pipe is divided into hot rolled pipe, cold rolled pipe, cold drawn pipe, extrusion pipe, pipe jacking and so on.

According to different uses, there are thick wall seamless steel pipes and thin wall seamless steel pipes.

Seamless steel pipe is mainly used for petroleum geological drilling pipe, petrochemical cracking pipe, boiler furnace pipe, bearing pipe and high-precision structural steel pipe for automobiles, tractors and aviation.

It is divided into two categories: general purpose (for water and gas pipelines and structural parts, mechanical parts) and special purpose (for boilers, geological exploration, bearings, acid resistance, etc.)

Petroleum Line Pipe

SMLS pipe refers to seamless steel pipe, which is made of a whole piece of metal and has no joints on the surface. According to the production method, seamless pipe is divided into hot rolled pipe, cold rolled pipe, cold drawn pipe, extrusion pipe, pipe jacking and so on.

According to different uses, there are thick wall seamless steel pipes and thin wall seamless steel pipes.

Seamless steel pipe is mainly used for petroleum geological drilling pipe, petrochemical cracking pipe, boiler furnace pipe, bearing pipe and high-precision structural steel pipe for automobiles, tractors and aviation.

It is divided into two categories: general purpose (for water and gas pipelines and structural parts, mechanical parts) and special purpose (for boilers, geological exploration, bearings, acid resistance, etc.)

Rectangular Tube Rectangular Steel Pipe

The Hollow section is divided into square and rectangular cold-formed hollow steel, referred to as square pipe and rectangular pipe. The square pipe is divided into hot-rolled seamless pipe, cold-drawn seamless pipe, extruded seamless pipe and welded square pipe according to the production process.

There are various surface treatment methods, including hot-dip galvanized, electric galvanized, oil coated, pickling, etc.

Hollow section applications mainly include: decoration, machine tool equipment, machinery industry, chemical industry, steel structure, shipbuilding, automobile manufacturing, steel beam and column, and other special purposes.

Square Tube

The Hollow section is divided into square and rectangular cold-formed hollow steel, referred to as square pipe and rectangular pipe. The square pipe is divided into hot-rolled seamless pipe, cold-drawn seamless pipe, extruded seamless pipe and welded square pipe according to the production process.

There are various surface treatment methods, including hot-dip galvanized, electric galvanized, oil coated, pickling, etc.

Hollow section applications mainly include: decoration, machine tool equipment, machinery industry, chemical industry, steel structure, shipbuilding, automobile manufacturing, steel beam and column, and other special purposes.

Square And Rectangular Tube

The Hollow section is divided into square and rectangular cold-formed hollow steel, referred to as square pipe and rectangular pipe. The square pipe is divided into hot-rolled seamless pipe, cold-drawn seamless pipe, extruded seamless pipe and welded square pipe according to the production process.

There are various surface treatment methods, including hot-dip galvanized, electric galvanized, oil coated, pickling, etc.

Hollow section applications mainly include: decoration, machine tool equipment, machinery industry, chemical industry, steel structure, shipbuilding, automobile manufacturing, steel beam and column, and other special purposes.

Galvanized Steel Pipe

The Hollow section is divided into square and rectangular cold-formed hollow steel, referred to as square pipe and rectangular pipe. The square pipe is divided into hot-rolled seamless pipe, cold-drawn seamless pipe, extruded seamless pipe and welded square pipe according to the production process.

There are various surface treatment methods, including hot-dip galvanized, electric galvanized, oil coated, pickling, etc.

Hollow section applications mainly include: decoration, machine tool equipment, machinery industry, chemical industry, steel structure, shipbuilding, automobile manufacturing, steel beam and column, and other special purposes.

Scaffolding system

Different types of engineering construction choose different uses of scaffolding.

Most of the bridge support frames use bowl buckle scaffolding, and there are also portal scaffolding.

The main structure construction of the ground scaffold using fastener scaffold is mostly, the longitudinal distance of scaffolding pole is generally 1.2~1.8m;

The transverse distance is generally 0.9~1.5m.

In the construction process, the use of scaffolding is very flexible, according to the specific construction requirements, the composition of different frame size, shape and carrying capacity of single and double rows of scaffolding, support frame, support column, material lifting frame, climbing scaffold, suspension frame and other functional construction equipment. It can also be used to build facilities, sheds, lighthouses and other structures.

Especially suitable for the erection of curved scaffolding and heavy support frame.

Scaffolding Swivel Coupler

Different types of engineering construction choose different uses of scaffolding.

Most of the bridge support frames use bowl buckle scaffolding, and there are also portal scaffolding.

The main structure construction of the ground scaffold using fastener scaffold is mostly, the longitudinal distance of scaffolding pole is generally 1.2~1.8m;

The transverse distance is generally 0.9~1.5m.

In the construction process, the use of scaffolding is very flexible, according to the specific construction requirements, the composition of different frame size, shape and carrying capacity of single and double rows of scaffolding, support frame, support column, material lifting frame, climbing scaffold, suspension frame and other functional construction equipment. It can also be used to build facilities, sheds, lighthouses and other structures.

Especially suitable for the erection of curved scaffolding and heavy support frame.

Scaffolding System Frame System

Different types of engineering construction choose different uses of scaffolding.

Most of the bridge support frames use bowl buckle scaffolding, and there are also portal scaffolding.

The main structure construction of the ground scaffold using fastener scaffold is mostly, the longitudinal distance of scaffolding pole is generally 1.2~1.8m;

The transverse distance is generally 0.9~1.5m.

In the construction process, the use of scaffolding is very flexible, according to the specific construction requirements, the composition of different frame size, shape and carrying capacity of single and double rows of scaffolding, support frame, support column, material lifting frame, climbing scaffold, suspension frame and other functional construction equipment. It can also be used to build facilities, sheds, lighthouses and other structures.

Especially suitable for the erection of curved scaffolding and heavy support frame.

Scaffolding Girder Coupler

Different types of engineering construction choose different uses of scaffolding.

Most of the bridge support frames use bowl buckle scaffolding, and there are also portal scaffolding.

The main structure construction of the ground scaffold using fastener scaffold is mostly, the longitudinal distance of scaffolding pole is generally 1.2~1.8m;

The transverse distance is generally 0.9~1.5m.

In the construction process, the use of scaffolding is very flexible, according to the specific construction requirements, the composition of different frame size, shape and carrying capacity of single and double rows of scaffolding, support frame, support column, material lifting frame, climbing scaffold, suspension frame and other functional construction equipment. It can also be used to build facilities, sheds, lighthouses and other structures.

Especially suitable for the erection of curved scaffolding and heavy support frame.

Cold Formed Sheet Pile

Steel sheet pile is a type of steel with lock, its section has straight plate shape, groove shape and Z shape, etc., there are various sizes and interlocking forms. Common ones are Larsen style, Lackawanna style and so on.

Its advantages are: high strength, easy to penetrate into the hard soil; Construction can be carried out in deep water, and diagonal supports are added to form a cage if necessary. Good waterproof performance; It can be formed according to the needs of various shapes of cofferdams, and can be reused many times, so it has a wide range of uses.

Steel sheet pile products are divided into two types according to the production process: cold-formed thin-wall steel sheet pile and hot-rolled steel sheet pile

Hot Rolled Sheet Pile

Steel sheet pile is a type of steel with lock, its section has straight plate shape, groove shape and Z shape, etc., there are various sizes and interlocking forms. Common ones are Larsen style, Lackawanna style and so on.

Its advantages are: high strength, easy to penetrate into the hard soil; Construction can be carried out in deep water, and diagonal supports are added to form a cage if necessary. Good waterproof performance; It can be formed according to the needs of various shapes of cofferdams, and can be reused many times, so it has a wide range of uses.

Steel sheet pile products are divided into two types according to the production process: cold-formed thin-wall steel sheet pile and hot-rolled steel sheet pile.

Vinyl PVC Sheet Pile

Steel sheet pile is a type of steel with lock, its section has straight plate shape, groove shape and Z shape, etc., there are various sizes and interlocking forms. Common ones are Larsen style, Lackawanna style and so on.

Its advantages are: high strength, easy to penetrate into the hard soil; Construction can be carried out in deep water, and diagonal supports are added to form a cage if necessary. Good waterproof performance; It can be formed according to the needs of various shapes of cofferdams, and can be reused many times, so it has a wide range of uses.

Steel sheet pile products are divided into two types according to the production process: cold-formed thin-wall steel sheet pile and hot-rolled steel sheet pile.

Bridge Constructure Structure

The basic components of a bridge include the upper structure, lower structure, support system, and ancillary facilities. The substructure refers to the part of a bridge located below the support, also known as the supporting structure, which includes piers, abutments, and the foundation of piers. The adjacent two span bridge is located in the middle of the bridge, and the basic concept of the box girder structure is that all upper structures become integral hollow beams. When the main load passes through any position on the bridge, all parts of the hollow beam (ribs, top plate, and bottom plate) participate in the force as a whole. The lower structure is usually made of steel plates, steel pipes, angle steels, H-beams, and other parts, which are welded together through components and ultimately connected on-site by welding or bolts. Xinyue can provide customers with design analysis, drawing splitting, steel production, welding and forming work, etc.

Pressure Bearing Construction Structure

The main load-bearing components of a building are divided into horizontal and vertical walls, which mainly bear horizontal and vertical loads. Column - a component that mainly bears vertical loads, used to support floor or roof loads, mainly divided into frame columns, component columns, etc. Beam - a horizontal load-bearing component used to support the load on floor or roof panels, mainly divided into square or cross shaped steel structures. The load-bearing structure places great emphasis on the quality of welding in production, and generally requires full fusion welding with very precise requirements for straightness and torsion. When it comes to complex welding component testing, in addition to conventional MT and UT testing, special testing molds need to be made to ensure that the dimensions of each small component are consistent with the drawing requirements.

Prefabricated Components Structure

Steel prefabricated components refer to assembly parts that are produced and processed to a certain extent in the factory, with an independent structural system, and can be directly transported to the construction site for installation. Common steel structure prefabricated components include steel beams, steel columns, steel bridge beams, steel structure floor slabs, etc. According to their application and form, they can be divided into frame prefabricated parts, plate prefabricated parts, steel pipe prefabricated parts, etc. The advantages of this structure include high strength, light weight, good overall stiffness, and strong resistance to deformation. It is particularly suitable for constructing large-span, ultra-high, and ultra-heavy buildings. After prefabrication in the factory, it can greatly save installation and welding work on the project site. Steel prefabricated components can be used for various types of mountain bridges, railway bridges, highway bridges, urban light rail bridges, substations, substations, ship structures, elevators, offshore platform structures, etc

LATEST NEWS

LATEST NEWS

- 2025-06-11Recently, Xinyue has reached an important cooperation with a new partner in Central Asia. As soon as the customer sent an inquiry, Xinyue responded promptly with a professional team, providing a comprehensive quotation package covering product specifications, price systems, and service guarantees, which helped the customer stand out in the bidding process and...

- 2025-06-10Seamless steel pipes are a type of pipe that is manufactured without any welds, making them strong and durable. This unique manufacturing process allows for a uniform structure, which provides superior resistance to pressure and internal impacts. One of the most significant advantages of seamless steel pipes is their ability to handle high pressure and temperature, making them ideal for various ap

- 2025-06-13Xinyue has recently established a partnership with a new client in Africa,providing high-quality steel products for their urgent project demands. With remarkable efficiency, we completed production and shipment in the shortest possible time,Once again, it exemplifies the pioneering and enterprising spirit of the Xinyue people, who are committed to achieving 100% customer satisfaction...

- 2025-06-05Recently, Xinyue successfully completed the supply of core products for the Central American submarine pipeline construction project, earning the trust of international customers with its professional technology and full-process services. The ordered products were concrete weight coating pipes, which were applied in the submarine high-pressure fluid transmission system. The technical complexity of this project posed extremely high requirements for the production process.